What is Hollow Shaft Stepper Motor?

A hollow shaft stepper motor is a type of stepper motor that features a central hole (or hollow shaft) running through its rotor. This design allows various elements—such as wires, pipes, rods, or shafts—to pass through the motor’s center, making it ideal for applications that require integrated movement or simplified mechanical design.

Features of a Hollow Shaft Stepper Motor

A hollow shaft stepper motor offers unique design and functional advantages that make it ideal for a wide range of high-precision applications. Below are the key features that define this specialized type of motor:

1. Central Hollow Shaft Design

The most distinctive feature is the open, through-hole center.

Allows cables, rods, optical fibers, or fluid tubes to pass through the motor.

Supports integration with rotary encoders, slip rings, or sensor wiring.

2. High Precision Stepping

Operates in discrete steps, enabling precise angular positioning.

Common step angles include 1.8°, 0.9°, or even microstepping options for smoother motion.

Ideal for applications requiring accurate rotation control.

3. Compact and Integrated Design

Combines motor and shaft space to save room in tight or compact systems.

Reduces the need for additional coupling parts or external components.

Enhances design flexibility and simplifies mechanical assemblies.

4. Strong Holding Torque

Offers high static torque when stationary, making it ideal for holding loads in place without movement.

Suitable for vertical or load-bearing positions without external brakes.

5. Easy Integration with Sensors or Gears

The hollow shaft can directly accommodate optical encoders, gearboxes, or timing pulleys.

Reduces mechanical complexity and alignment errors.

6. Reliable Open-Loop Control

Often used without feedback systems, simplifying the electronics and control.

Some advanced models support closed-loop feedback for added precision.

7. Versatility in Mounting and Orientation

Can be mounted in multiple configurations due to symmetrical shaft design.

Adaptable for use in robotic arms, CNC machines, turntables, and other rotating systems.

8. Low Maintenance and High Durability

9. Energy Efficient

10. Customization Options

Available in various sizes (e.g., NEMA 17, 23, 34).

Custom hollow shaft diameters and lengths to suit specific applications.

How Does a Hollow Shaft Stepper Motor Work?

A hollow shaft stepper motor works on the same basic principle as a traditional stepper motor but with a unique through-hole shaft design that offers added flexibility in integration. Here's a clear breakdown of how it functions:

1. Electromagnetic Stepping Principle

Inside the motor are multiple coils (windings) arranged in phases.

These coils are energized in a specific sequence to create rotating magnetic fields.

The rotor (the rotating part of the motor) aligns with these magnetic fields.

Each time the current shifts to the next phase, the rotor “steps” forward by a precise angle (commonly 1.8° per step for a 200-step motor).

2. Hollow Shaft Functionality

Instead of a solid central shaft, a hollow tube runs through the center of the rotor.

This design allows wires, pipes, shafts, or sensors to pass through the motor.

The hollow shaft still rotates along with the rotor, allowing it to transmit torque and motion like a normal stepper motor.

It also makes it easier to integrate with rotary encoders, slip rings, or central drive shafts.

3. Step-by-Step Rotation

The controller sends pulse signals to the motor driver.

For each pulse, the motor moves one fixed step forward.

The more pulses sent, the further the motor rotates.

The rotation direction depends on the order of the energized phases.

4. Holding and Positioning

Even when not rotating, the motor can hold its position by keeping current in the windings.

This makes it ideal for applications where the load must stay in a fixed position without slipping.

5. Microstepping (Optional)

In advanced systems, microstepping divides each full step into smaller increments.

This creates smoother motion and better positional accuracy.

In Summary:

A hollow shaft stepper motor converts electrical pulses into precise mechanical movement, just like a regular stepper motor. However, its unique hollow center allows for more complex and compact system designs by letting components pass through the center of the motor while still providing accurate, step-by-step rotation.

This makes it an excellent choice for:

It’s a smart solution for any system needing precise control + design flexibility.

BesFoc Hollow Shaft Stepper Motor Kinds:

BesFoc is a prfessional Stepper Motor and Bldc Motor Manufacturer with 15 years experience, if you need any customized motors, click this link to contact us now!!!

Types of Hollow Shaft Stepper Motors

Hollow shaft stepper motors come in a variety of designs tailored to meet the specific needs of precision-driven systems. While they all share the signature central through-hole shaft, they differ in construction, performance, and applications. Below are the main types of hollow shaft stepper motors, each with unique characteristics.

1. Permanent Magnet (PM) Hollow Shaft Stepper Motor

Uses a permanent magnet rotor and a single stator winding.

Offers moderate resolution and low torque.

Simple and cost-effective, best for low-end applications or basic positioning systems.

Not commonly used in high-precision or industrial tasks.

2. Variable Reluctance (VR) Hollow Shaft Stepper Motor

Operates without permanent magnets; rotor is made of soft iron.

Provides high step resolution but lower torque.

Suitable for applications that prioritize speed and accuracy over torque, such as optical instruments and fine-tuned adjustments.

3. Hybrid Hollow Shaft Stepper Motor

Combines the features of both PM and VR motors.

Most common and widely used type in industrial applications.

Offers high torque, fine resolution, and excellent stability.

Available with microstepping and closed-loop feedback options.

Ideal for robotics, automation, CNC systems, and semiconductor equipment.

4. Closed-Loop Hollow Shaft Stepper Motor

Equipped with built-in encoders to monitor position in real time.

Eliminates missed steps and improves reliability.

Offers servo-like performance while retaining stepper motor cost efficiency.

Common in medical devices, robotic arms, and 3D printers where accuracy is critical.

5. Hollow Shaft Stepper Motor with Integrated Driver

Includes an onboard motor driver or controller, reducing wiring complexity.

Plug-and-play solution for quick system integration.

Suitable for compact machinery, portable systems, and smart automation platforms.

6. Frameless Hollow Shaft Stepper Motor

Delivered as rotor and stator kits, without an external frame.

Allows OEMs to directly integrate the motor into their mechanical design.

Perfect for custom equipment, robotic joints, or highly space-constrained environments.

7. Hollow Shaft Stepper Motor with Gearbox

Combined with a planetary or harmonic gearbox for higher torque and lower speed.

Maintains precision while handling heavier loads.

Used in rotary tables, indexers, and material handling systems.

8. Flat (Pancake) Hollow Shaft Stepper Motor

Ultra-thin profile with a wide diameter and central hole.

Designed for applications with limited axial space.

Common in camera systems, gimbals, and rotary stages.

Conclusion:

There are several types of hollow shaft stepper motors available to match various engineering challenges. Whether you need high precision, space efficiency, or heavy-load capabilities, there's a hollow shaft motor tailored to your application's unique requirements. Their adaptability and advanced motion control features make them an essential choice in today’s smart automation and robotic systems.

Top 20 Hollow Shaft Stepper Motor Manufacturers in China

When it comes to precision motion control, hollow shaft stepper motors are integral to countless industrial and automation applications. China has emerged as a global leader in manufacturing high-performance stepper motors, including specialized hollow shaft stepper motors that meet the rigorous demands of robotics, CNC machinery, 3D printing, and more. Below is a curated list of the top 20 hollow shaft stepper motor manufacturers in China, highlighting their company profiles, main products, and key advantages.

1. Leadshine Technology Co., Ltd.

Company Profile

Founded in 1997 and headquartered in Shenzhen, Leadshine is a renowned hollow shaft stepper motor manufacturer in the motion control industry with a global presence in over 50 countries.

Main Products

Advantages

Exceptional product stability

Global after-sales service

In-house R&D and manufacturing

2. Changzhou Fulling Motor Co., Ltd.

Company Profile

Established in 2001, Fulling Motor is located in Changzhou, Jiangsu. The company is a leading hollow shaft stepper motor manufacturer and specializes in stepper and BLDC motors and supplies to over 30 countries.

Main Products

NEMA hollow shaft stepper motors

Permanent magnet stepper motors

Integrated stepper motor drivers

Advantages

3. MOONS’ Industries (Shanghai) Co., Ltd.

Company Profile

Founded in 1994, MOONS’ is a technology-driven hollow shaft stepper motor manufacturer focusing on motion control, intelligent lighting, and industrial automation solutions.

Main Products

Advantages

4. Shenzhen Just Motion Control Electromechanics Co., Ltd.

Company Profile

Just Motion Control (JMC) is based in Shenzhen and has established itself as a reliable hollow shaft stepper motor manufacturer of industrial-grade motion control systems.

Main Products

Hollow shaft stepper motors

Closed-loop stepper motors

Motor drivers and controllers

Advantages

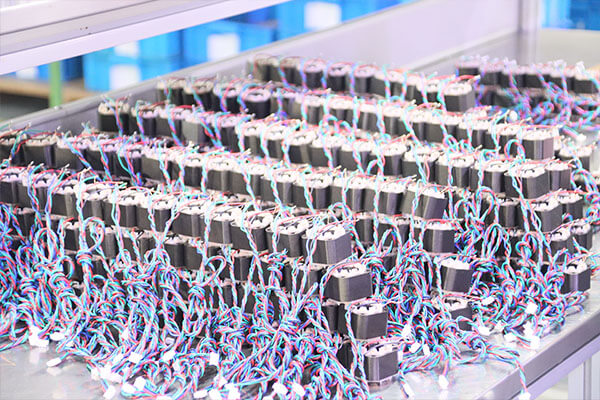

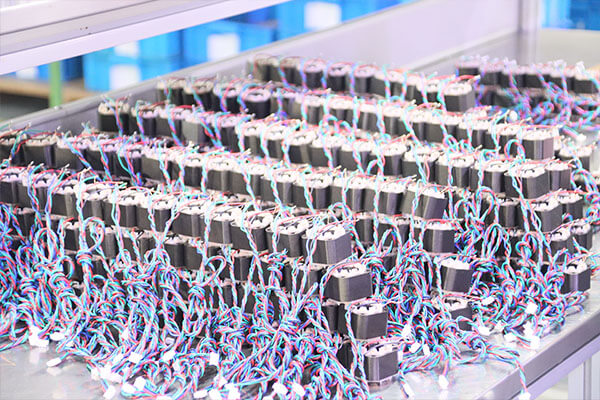

5. Changzhou BesFoc Motor Co., Ltd.

Company Profile

With decades of manufacturing experience, BesFoc Motor is one of the trusted hollow shaft stepper motor manufacturers in the motor components sector.

Main Products

Advantages

Strong focus on OEM/ODM services

Low MOQ with high-quality assurance

Advanced CNC production lines

6. Shenzhen VEXTA Precision Motor Co., Ltd.

Company Profile

A hollow shaft stepper motor manufacturer and specialized in high-precision motor components, VEXTA operates under strict quality control measures to ensure top-tier performance.

Main Products

Advantages

High torque in compact design

Suitable for medical and laboratory use

Custom design capabilities

7. Ningbo Haishu Shuangyuan Micro Motor Factory

Company Profile

A family-owned hollow shaft stepper motor manufacturer with more than 15 years of experience, Shuangyuan focuses on precision mini motors for a variety of applications.

Main Products

Advantages

8. Zhejiang Leili Motor Co., Ltd.

Company Profile

Leili Motor is a publicly listed company and one of the largest hollow shaft stepper motor manufacturers in China, serving clients in over 40 countries.

Main Products

Advantages

9. Changzhou Wanshsin Micro Motor Co., Ltd.

Company Profile

Wanshsin is a hollow shaft stepper motor manufacturer and specializes in customized motor solutions and is located in the heart of China’s motor manufacturing hub, Changzhou.

Main Products

Advantages

10. Shenzhen Zhaowei Machinery & Electronics Co., Ltd.

Company Profile

Zhaowei is a high-tech hollow shaft stepper motor manufacturer that focuses on precision drive systems and smart control.

Main Products

Hollow shaft precision stepper motors

Drive modules and gear motors

Integrated actuator systems

Advantages

11. Kegu Motor Co., Ltd.

Company Profile

Kegu Motor is a hollow shaft stepper motor manufacturer and specializes in the design and production of precision motors including customized hollow shaft models.

Main Products

Advantages

12. Changzhou JKONGMOTOR Co., Ltd.

Company Profile

As a professional hollow shaft stepper motor manufacturer and known for flexible production and quick delivery, JKONGMOTOR offers innovative solutions tailored to automation needs.

Main Products

Hollow shaft stepper motors

Integrated stepper drivers

Motorized linear actuators

Advantages

13. Jiangsu DINGS' Electrical & Mechanical Technology Co., Ltd.

Company Profile

DINGS’ is a leading hollow shaft stepper motor manufacturer and specializes in closed-loop stepper motor systems and offers advanced mechatronic integration.

Main Products

Advantages

14. Kinmore Motor Co., Ltd.

Company Profile

With over 20 years in the motor industry, Kinmore provides motor solutions to industries such as smart home, security, and automotive.

Main Products

Hollow shaft mini stepper motors

Brushed and brushless motors

Automotive actuator motors

Advantages

15. Shenzhen Pengchuang Weiye Technology Co., Ltd.

Company Profile

PCWY Technology is a hollow shaft stepper motor manufacturer in automation components, providing cost-effective motion control solutions.

Main Products

Advantages

16. Changzhou Songyang Machinery & Electronics Co., Ltd.

Company Profile

Songyang is a hollow shaft stepper motor manufacturer and focuses on the production of motors for precise positioning systems and is ISO 9001 certified.

Main Products

Advantages

Industry-grade reliability

Flexible engineering solutions

Competitive turnaround times

17. Suzhou Micro Actuator Technology Co., Ltd.

Company Profile

A hollow shaft stepper motor manufacturer in high-precision and miniaturized motor systems, Suzhou Micro serves tech and medical markets worldwide.

Main Products

Mini hollow shaft motors

Linear micro motors

Positioning platforms

Advantages

18. Wantai Motor (Changzhou) Co., Ltd.

Company Profile

Wantai Motor is a globally recognized hollow shaft stepper motor manufacturer for CNC and 3D printer motors, offering a wide range of stepper solutions.

Main Products

Advantages

19. Dongguan YCT Electronics Co., Ltd.

Company Profile

Located in Dongguan, YCT is a hollow shaft stepper motor manufacturer in electromechanical components used in automation and robotics.

Main Products

Advantages

20. Shanghai Sine Electric Co., Ltd.

Company Profile

Shanghai Sine is a full-solution hollow shaft stepper motor manufacturer for stepper motor systems and has a strong presence in both domestic and international markets.

Main Products

Advantages

Advantages of Hollow Shaft Stepper Motors

Hollow shaft stepper motors combine the precision of stepper technology with a versatile through-hole design, making them a popular choice in advanced engineering and automation. Here are the key advantages of using hollow shaft stepper motors:

1. Central Access for Integration

The hollow shaft allows cables, shafts, pipes, or optical fibers to pass directly through the center of the motor.

This simplifies the mechanical layout, especially in rotary platforms, robotic arms, and automated machinery.

2. Space-Saving Design

By eliminating the need for external couplings or routing systems, hollow shaft motors reduce the overall size of the mechanical setup.

Ideal for compact systems where space efficiency is critical.

3. Simplified Assembly

The ability to run components through the motor's center makes assembly and alignment easier and faster.

Reduces the number of mechanical parts, which lowers manufacturing complexity and maintenance needs.

4. Precise Positioning and Control

Like traditional stepper motors, hollow shaft stepper motor models provide accurate step-by-step rotation.

Perfect for applications requiring reliable motion control, such as robotics, 3D printing, and CNC machines.

5. Flexible Mounting Options

The symmetrical shaft design supports various installation orientations.

Can be integrated with slip rings, encoders, or gearboxes directly inside or through the hollow shaft.

6. Reduced Cable Stress

Cables or hoses that pass through the motor are protected and remain stationary, reducing twisting, bending, or damage.

Improves durability in rotating or continuously moving systems.

7. High Torque and Holding Power

Offers strong torque output per frame size, ideal for holding loads without movement when the motor is idle.

Useful in vertical lifting applications, positioning platforms, and indexers.

8. Versatile Application Range

9. Compatibility with Advanced Features

Easily combined with microstepping drives, closed-loop control, or servo-like enhancements.

Offers greater smoothness and precision in motion-critical applications.

10. Enhanced System Aesthetics and Cable Management

Internal cable routing through the hollow shaft leads to cleaner, more professional designs.

Reduces clutter and improves overall system reliability.

Applications of a Hollow Shaft Stepper Motor

A hollow shaft stepper motor is a precision-driven, compact, and highly adaptable motion control device used across many industries. Its unique through-shaft design allows engineers to create integrated, space-saving systems that maintain exceptional positioning accuracy. Below are the most common and high-value applications where hollow shaft stepper motors are widely used:

1. Robotics and Automation Systems

Rotary joints and arms: Wires, sensors, or air tubes can pass through the motor, enabling clean and flexible rotation in robotic arms and grippers.

Collaborative robots (cobots): The compact design helps reduce joint size while maintaining torque and control.

2. Semiconductor Manufacturing Equipment

Used in wafer handlers, pick-and-place machines, and inspection stations.

The hollow shaft supports rotary encoders or vacuum lines for ultra-clean environments and precision movement.

3. CNC Machines and Indexing Tables

Ideal for rotary indexing, where the center hole allows cables or clamping fixtures to pass through the spindle.

Ensures high positional accuracy for automated drilling, milling, or component rotation.

4. Medical Devices and Imaging Equipment

Found in CT scanners, MRI beds, surgical robots, and lab automation tools.

The hollow shaft permits fiber optics, wires, or tubing to move through the motor safely and hygienically.

5. Camera Gimbals and Pan-Tilt Systems

Used in surveillance cameras, drones, and stabilization platforms.

The hollow shaft allows camera cables to pass through without tangling, enabling 360-degree continuous rotation.

6. Printing and Packaging Machinery

Supports rotary cutters, rollers, and label applicators.

Internal shaft access allows for tension control, pneumatic tubing, or sensor wiring directly through the motor.

7. Aerospace and Defense Systems

Utilized in satellite antenna positioning, targeting platforms, and navigation systems.

Offers compact size, low weight, and high reliability under extreme conditions.

8. Textile Machinery

Deployed in spinning, weaving, and embroidery machines for precise thread or component control.

Hollow shaft helps route control wires or mechanical links internally.

9. Lab Automation and Analysis Equipment

Common in centrifuges, sample handling arms, and fluidic systems.

The shaft can carry sample tubes or control lines, making the system cleaner and more efficient.

10. Slip Ring Integration for Continuous Rotation

Hollow shaft motors are often paired with slip rings to allow uninterrupted electrical connection during full rotation.

This is essential in radar systems, machine vision platforms, and automated rotary tables.

Why These Applications Matter

The real advantage of hollow shaft stepper motors lies in their ability to provide:

Compact, clean, and clutter-free system design

High-precision motion control

Increased flexibility for rotating systems

Simplified cable management

Enhanced integration with sensors and feedback systems

How to Choose the Right Hollow Shaft Stepper Motor

Selecting the right hollow shaft stepper motor is crucial for ensuring optimal performance, durability, and integration within your system. Whether you're designing an industrial automation system, a robotic arm, or medical imaging equipment, the right motor will deliver precision, efficiency, and long-term reliability.

Here’s a step-by-step guide on how to choose the ideal hollow shaft stepper motor for your specific application:

1. Define Your Application Requirements

Start by clearly understanding what your system needs:

Torque Requirements:

How much rotational force does your application need? Heavy-load applications require motors with high holding and dynamic torque.

Speed:

Determine the maximum and minimum RPM (revolutions per minute) the motor must achieve without losing steps or overheating.

Load Type:

Consider whether your motor will drive a rotary table, pulley, gear, or direct load.

2. Shaft Size and Hollow Diameter

The hollow shaft diameter must accommodate the components you need to pass through the center—such as cables, air lines, or optical fibers.

Ensure it matches your system design and space constraints.

3. Step Angle and Precision

Most standard stepper motors offer 1.8° or 0.9° per step.

For higher precision, choose motors with microstepping capability.

Closed-loop systems can offer servo-level accuracy with feedback control.

4. Frame Size and Mounting Dimensions

Select a motor with a frame size (e.g., NEMA 17, 23, or 34) that fits your available mounting area.

Ensure it supports the correct bolt pattern and shaft alignment.

5. Holding Torque vs. Running Torque

Holding torque is the ability to resist motion when stationary.

Running torque is how much the motor can deliver while moving.

Choose a motor that maintains adequate torque under your load conditions, especially if the system stops and starts frequently.

6. Voltage and Current Ratings

7. Closed-Loop vs. Open-Loop

Open-loop motors are cost-effective and simpler, but can lose steps if overloaded.

Closed-loop motors have encoders for real-time position feedback, ensuring accurate motion even under dynamic loads.

8. Environmental Conditions

Consider the motor’s resistance to dust, moisture, temperature, and vibration.

For harsh environments, look for motors with sealed housings (IP ratings) and robust construction.

9. Integration Needs

Some motors come with integrated drivers or gearboxes, reducing wiring and simplifying setup.

Others are frameless or customizable for OEM applications where space or weight is critical.

10. Budget and Lifecycle Cost

Don’t just consider the upfront cost—factor in maintenance, efficiency, and potential downtime.

A slightly higher investment in a high-efficiency, closed-loop motor may save significant costs over time.

Quick Selection Checklist

| Factor | Considerations |

| Torque | Load weight, acceleration/deceleration needs |

| Speed | Required RPM under load |

| Shaft Size | Inner diameter requirements |

| Precision | Step angle and microstepping capabilities |

| Frame Size | Fitment and space constraints |

| Voltage & Current | Match with driver/controller specs |

| Feedback Option | Closed-loop for accuracy, open-loop for simplicity |

| Environmental Protection | IP rating, temperature, dust exposure |

| Integration | Gearboxes, encoders, built-in drivers |

| Budget | Consider total cost of ownership, not just motor price |

Conclusion:

Choosing the right hollow shaft stepper motor means balancing performance, space, integration, and cost. By carefully analyzing your application’s needs and comparing them with motor specifications, you can ensure efficient, reliable, and accurate motion control for years to come.

Conclusion:

From robotics to aerospace, hollow shaft stepper motors have become essential in modern mechatronic systems. Their unmatched ability to combine precision with mechanical versatility makes them a top choice in industries requiring advanced, space-efficient automation.

Hollow shaft stepper motors offer a powerful blend of mechanical innovation and precise motion control. Their unique structure enables space-efficient, flexible, and high-performance solutions for modern engineering challenges. Whether you're designing industrial robots or compact medical systems, these motors provide a smart and efficient motion solution.

These top 20 Chinese hollow shaft stepper motor manufacturers of hollow shaft stepper motors are reshaping the future of automation with innovation, precision, and cost-efficiency. Whether you're sourcing motors for CNC, robotics, or industrial control, these companies offer world-class solutions that align with international standards.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Oʻzbekcha

latviešu

Azərbaycan dili

Български

Català