Introduction

Linear actuators are essential components in a wide range of applications, from industrial automation to home automation systems. These devices convert rotational motion into linear motion, providing the precise movement needed in various mechanical operations. Whether you’re looking to automate a process or enhance the efficiency of machinery, understanding the functionality, types, and applications of linear actuators is crucial.

Understanding the Basics

What is a Linear Actuator?

A linear actuator is a device that creates motion in a straight line, as opposed to the circular motion of a conventional electric motor. This linear motion is essential in many applications where objects need to be moved or positioned in a straight path. Linear actuators are widely used in various industries, including manufacturing, robotics, medical devices, and even consumer electronics.

How Does a Linear Actuator Work?

Linear actuators operate based on a simple principle: they convert the rotational motion of a motor into linear displacement. This is achieved through different mechanisms, including screws, gears, and belts. The most common types of linear actuators include:

Electric Linear Actuators: Utilize an electric motor to drive a screw, which in turn moves the actuator shaft in a straight line.

Hydraulic Linear Actuators: Use fluid pressure to drive a piston, creating linear motion.

Pneumatic Linear Actuators: Operate using compressed air to move a piston in a straight line.

Each type of actuator has its unique advantages and is selected based on the specific requirements of the application.

Types of Linear Actuators

1. Electric Linear Actuators

Electric linear actuators are among the most commonly used types due to their versatility and ease of control. They are powered by electric motors and can be designed to provide both high speed and high precision. Electric actuators are ideal for applications requiring precise positioning, such as robotics, home automation, and industrial machinery.

AC and DC Actuators: These actuators can be powered by either alternating current (AC) or direct current (DC) sources. AC actuators are typically used in industrial applications, while DC actuators are more common in automotive and home automation systems.

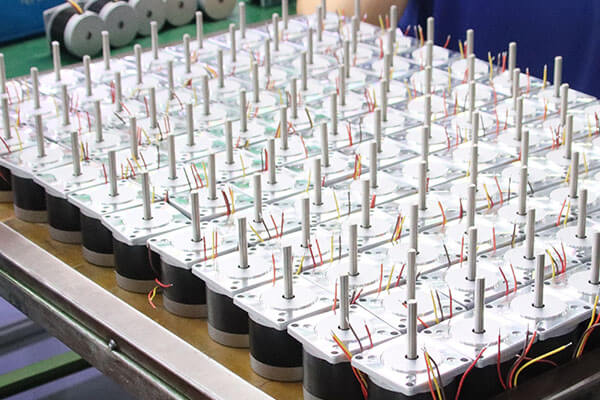

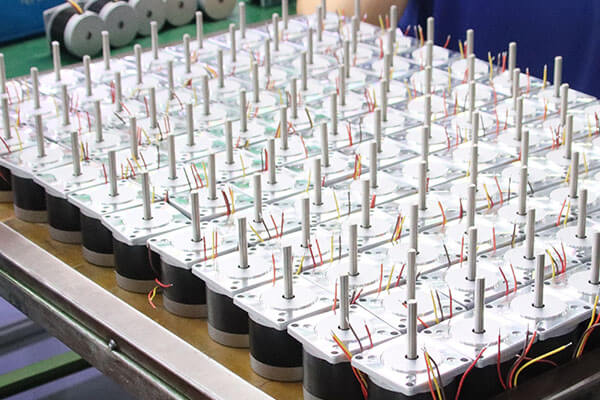

Stepper Motor Actuators: These actuators use a stepper motor, which allows for precise control of the movement and positioning of the actuator.

Servo Motor Actuators: Similar to stepper motors but provide closed-loop control, making them ideal for applications requiring high precision and feedback.

2. Hydraulic Linear Actuators

Hydraulic actuators are known for their ability to generate a significant amount of force, making them ideal for heavy-duty applications. These actuators use a hydraulic fluid to create pressure, which then moves a piston in a linear direction. Hydraulic actuators are commonly used in construction equipment, manufacturing machinery, and any application where high force and durability are required.

Single-Acting Hydraulic Actuators: Operate in one direction only, with a return spring or gravity used to return the actuator to its original position.

Double-Acting Hydraulic Actuators: Can operate in both directions, providing greater control and flexibility in applications requiring bi-directional movement.

3. Pneumatic Linear Actuators

Pneumatic actuators operate similarly to hydraulic actuators but use compressed air instead of hydraulic fluid. They are typically used in applications where lower force is sufficient but rapid movement is required. Pneumatic actuators are commonly found in material handling systems, packaging machinery, and other automation systems.

Rodless Pneumatic Actuators: These actuators do not have an external rod and are ideal for applications where space is limited.

Rod-Style Pneumatic Actuators: Feature an external rod and are used in applications where high precision is not as critical.

Key Components of a Linear Actuator

Motor

The motor is the heart of the linear actuator, providing the energy needed to drive the motion. Depending on the type of actuator, this could be an electric motor, a hydraulic pump, or a pneumatic compressor.

Screw or Cylinder

The screw or cylinder is the component that physically moves in a straight line. In an electric actuator, this might be a lead screw, while in a hydraulic or pneumatic actuator, it could be a cylinder.

Control Unit

The control unit manages the operation of the actuator, ensuring that it moves to the correct position with the desired speed and force. This is often done using sensors and feedback mechanisms.

Feedback Mechanism

Feedback mechanisms, such as encoders or potentiometers, provide information about the position of the actuator, allowing for precise control over its movement.

Applications of Linear Actuators

Linear actuators are incredibly versatile and can be found in a wide range of applications. Here are some of the most common uses:

1. Industrial Automation

In the industrial sector, linear actuators are used to automate machinery and processes. They provide the precise movement required for tasks such as material handling, assembly line automation, and packaging. Electric linear actuators are particularly popular in this field due to their precision and control capabilities.

2. Robotics

Robotics is another area where linear actuators play a critical role. They are used to control the movement of robotic arms, grippers, and other components, allowing robots to perform tasks with high accuracy and repeatability. Both electric and pneumatic actuators are commonly used in robotics, depending on the specific requirements of the application.

3. Medical Devices

Linear actuators are also widely used in medical devices, where precise control of movement is essential. They are found in hospital beds, surgical tables, and diagnostic equipment, providing the necessary adjustments and positioning for patient care and medical procedures.

4. Home Automation

Home automation systems often use linear actuators to control various functions, such as adjusting blinds, opening windows, and even controlling home theater systems. DC actuators are commonly used in these applications due to their compact size and ease of integration into existing systems.

5. Automotive Industry

In the automotive industry, linear actuators are used in a variety of applications, from adjusting seats and mirrors to controlling engine components. Electric actuators are particularly popular in this industry due to their reliability and ease of use.

Advantages of Using Linear Actuators

Precision and Control

One of the main advantages of linear actuators is their ability to provide precise and controlled movement, which is essential in applications that require accuracy.

Energy Efficiency

Many linear actuators, especially electric ones, are highly energy-efficient, converting energy into motion with minimal losses.

Versatility

Linear actuators are used in a wide range of applications, from simple home automation tasks to complex industrial machinery, making them incredibly versatile.

Low Maintenance

Most linear actuators are designed to be durable and require minimal maintenance, which reduces downtime and operational costs.

Challenges and Considerations

Load Capacity

One of the key challenges when choosing a linear actuator is ensuring that it can handle the required load without failure.

Speed vs. Force Trade-Off

In many cases, there is a trade-off between speed and force. High-speed actuators may not be able to exert as much force, so it's important to balance these factors based on the application.

Environmental Factors

Temperature, humidity, and exposure to corrosive substances can all affect the performance of a linear actuator, so these factors need to be considered when selecting one.

Cost Considerations

While linear actuators offer many benefits, they can also be expensive, especially for high-performance models. It's important to weigh the costs against the benefits for each specific application.

Future Trends in Linear Actuators

Integration with IoT

As the Internet of Things (IoT) continues to expand, we can expect to see more linear actuators that are connected to the internet, allowing for remote monitoring and control.

Advancements in Materials

New materials, such as lightweight composites and advanced polymers, are making linear actuators more efficient and durable.

Miniaturization

As technology advances, there is a growing demand for smaller, more compact linear actuators that can be used in applications where space is limited.

Improved Energy Efficiency

Future linear actuators are likely to be even more energy-efficient, with innovations that reduce power consumption while maintaining or even improving performance.

Conclusion

Linear actuators play a critical role in a wide variety of industries, providing the precise and controlled linear motion needed for countless applications. From industrial automation to home automation, their versatility and efficiency make them indispensable. As technology continues to evolve, we can expect linear actuators to become even more advanced, opening up new possibilities for innovation.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Oʻzbekcha

latviešu

Azərbaycan dili

Български

Català