Introduction

Integrated stepper motors are at the heart of countless automation and control systems across industries. With China being one of the largest manufacturing hubs in the world, it's no surprise that many of the top players in the stepper motor market are based there. In this article, we will explore the top 20 integrated stepper motor manufacturers in China, highlighting their key products, technological innovations, and global influence in the industry.

What Are Integrated Stepper Motors?

Introductions to Integrated Stepper Motors

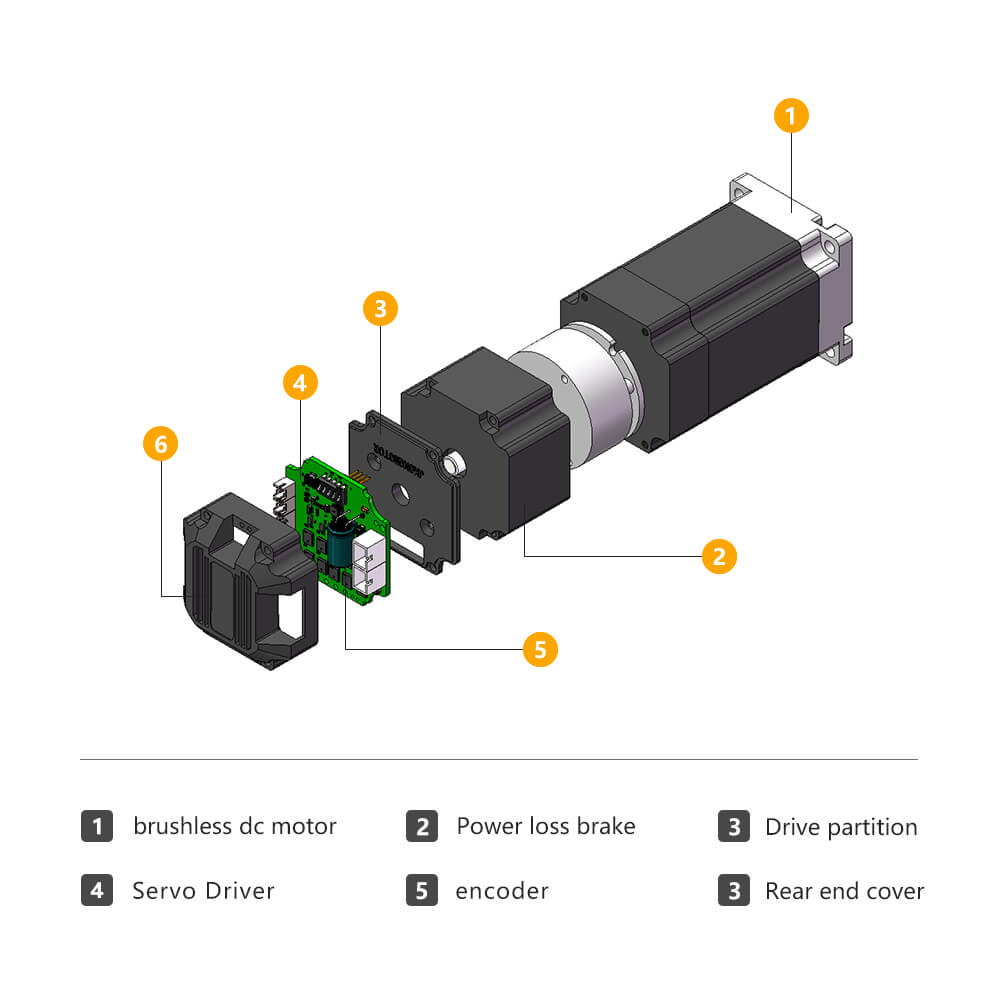

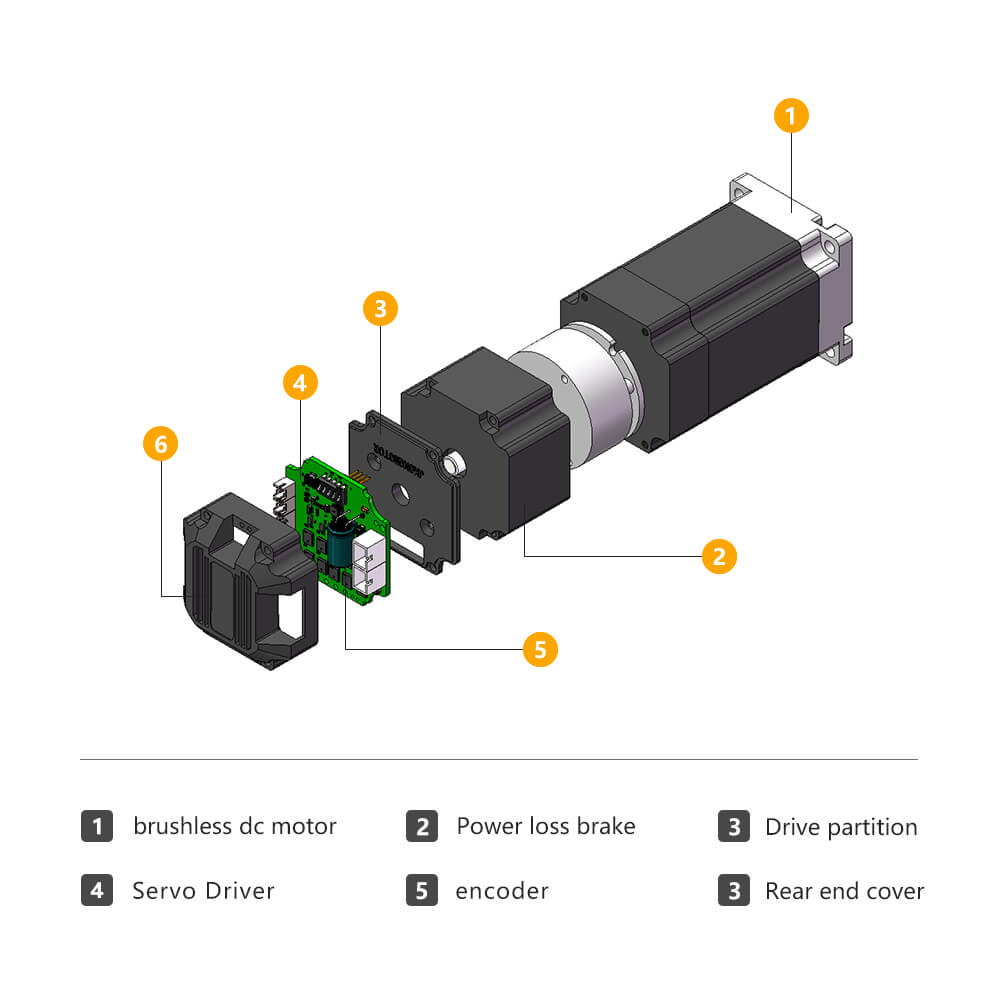

Integrated stepper motors are a type of stepper motor where the motor and its controller are combined into one compact unit. Unlike traditional stepper motors, which require an external controller to function, integrated stepper motors simplify the setup by incorporating both the motor and the necessary electronics inside the same housing.

In a standard stepper motor system, the motor itself generates the movement, while the controller is responsible for sending electrical signals that dictate how the motor moves. In an integrated stepper motor, these two components are combined, so the motor can operate directly with a simplified connection to power, making installation and use much easier.

How Do Integrated Stepper Motors Differ from Regular Stepper Motors?

Single Unit Design:

The key difference is that an Integrated stepper motor comes as a self-contained unit, which includes both the stepper motor and the controller, reducing the complexity of wiring and external components.

Simplified Installation:

With integrated motors, users don’t need to worry about matching the motor with an appropriate driver or controller. This makes it easier and faster to set up systems that require stepper motors.

Compact and Efficient:

Integrated stepper motors tend to be more compact than traditional systems, offering a space-saving design that’s ideal for applications where space is limited.

Cost-Effective:

Since the controller is built into the motor, there’s no need for separate components, which can reduce overall costs, particularly for systems that use multiple motors.

Applications of Integrated Stepper Motors

Integrated stepper motors are used in various fields where precision, control, and compactness are needed. Some of the most common applications include:

3D Printing: Integrated stepper motors provide the precision needed to control the movement of printheads and build platforms.

Robotics: Robots require precise movements for tasks like assembly, picking, and placing, and integrated stepper motors deliver that.

CNC Machines: In computer numerical control (CNC) systems, integrated stepper motors are used for driving machine components such as routers, lathes, and mills.

Medical Equipment: Devices like surgical robots, diagnostic tools, and imaging machines often use integrated stepper motors for smooth, reliable motion control.

Benefits of Integrated Stepper Motors

Simplified Control:

The motor and controller in one unit means there are fewer components to manage, simplifying the control system.

Energy Efficiency:

With modern Integrated stepper motors, power consumption is optimized, reducing wasted energy and increasing the efficiency of systems.

Reduced Noise:

Integrated stepper motors often feature quieter operation compared to traditional stepper motors, making them ideal for noise-sensitive environments like medical labs or offices.

Higher Reliability:

Fewer external connections mean there are fewer points of failure, making integrated stepper motors a more reliable choice for long-term use.

In conclusion, integrated stepper motors offer a more efficient, compact, and user-friendly solution compared to traditional stepper motor systems, making them an ideal choice for a wide range of modern applications in automation, robotics, medical technology, and more.

Why China Dominates the Stepper Motor Market

China's dominance in the stepper motor market is driven by a combination of factors, including its manufacturing prowess, cost-effectiveness, technological innovation, skilled workforce, and robust supply chain. As the demand for automation and precision-driven systems continues to rise, China’s role as a global leader in stepper motor production will only grow. For businesses looking for reliable, affordable, and high-performance stepper motors, China remains the go-to destination for sourcing quality products.

Top 20 Integrated Stepper Motor Manufacturers in China

1. Oriental Motor (China) Co., Ltd.

Oriental Motor is a global leader in the stepper motor industry, with a significant presence in China. They offer a wide range of integrated stepper motors designed for various industrial applications, including robotics, automation, and medical equipment.

2. Nidec Corporation

Nidec Corporation is another key player in the stepper motor market. Their Chinese operations focus on producing high-precision integrated motors that are used in a variety of fields, from automotive to consumer electronics.

3. Leadshine Technology Co., Ltd.

Leadshine is known for its focus on integrated stepper motors that offer high torque and energy efficiency. They cater to a diverse range of industries, including 3D printing, robotics, and CNC machinery.

4. MinebeaMitsumi Inc.

MinebeaMitsumi is a global manufacturer with a significant presence in China. Their integrated stepper motors are known for their reliability and performance, making them a popular choice for high-precision applications.

5. Moons’ Industries Co., Ltd.

Moons’ Industries is a leader in Integrated stepper motors technology. They specialize in motors with high torque density and efficiency, which makes them ideal for applications in industrial automation, robotics, and more.

6. SANYO DENKI (China)

SANYO DENKI’s integrated stepper motors are renowned for their high precision and smooth motion control. They are particularly popular in the robotics and automation industries, where precision is paramount.

7. Changzhou BesFoc Motor Co., Ltd.

BesFoc integrated stepper motors support pulse rs485 canopen and ethercat communication control with IP30, IP54, IP65 waterproof level, and the gearbox, brake, encoder, drivers are optional. Their products are exported to more than 30 countries and regions, such as the United States, Germany, Switzerland, Italy, France and so on.

8. STMicroelectronics

STMicroelectronics operates numerous manufacturing facilities in China, producing a range of integrated stepper motors. Known for their technological advancements, their products are widely used in consumer electronics and industrial applications.

9. Jiangsu Sifang Automation Co., Ltd.

Jiangsu Sifang specializes in automation and control systems, offering integrated stepper motors for precision-driven tasks in industries like automotive, robotics, and manufacturing.

10. Shenzhen NANYA Technology Co., Ltd.

Shenzhen NANYA offers a range of cutting-edge integrated stepper motors that are used in high-precision applications like robotics, 3D printing, and medical technology.

11. Yaskawa Electric Corporation (China)

Yaskawa Electric, with a strong presence in China, produces high-performance integrated stepper motors that are integral to the robotics and manufacturing sectors.

12. Changzhou Jkongmotor Co., Ltd.

Changzhou Jkongmotor Integrated servo motors include integrated stepper servo motors and integrated brushless dc motors which apply for medical equipment, logistics transportation, industrial automation, textile machinery, laser, drawing, traditional Chinese medicine ingredient industry, etc. Jkongmotor also is a comprehensive company which specializes in producing and researching stepper motor and motor driver, closed loop stepper motor, step servo motor, brushless dc motor, brushless dc driver, spindle motor.

13. Beijing Xihu Electric Co., Ltd.

Beijing Xihu Electric focuses on producing integrated stepper motors with high efficiency and durability, ensuring their products can stand up to demanding industrial environments.

14. Shenglong Motor Co., Ltd.

Shenglong Motor provides integrated stepper motors tailored to the specific needs of their clients, with a focus on industrial automation and custom solutions.

15. Guangzhou Kangou Motor Co., Ltd.

Kangou Motor offers a variety of Integrated stepper motors, with a particular emphasis on energy-saving solutions for industries such as textile manufacturing and medical equipment.

16. Hunan Yuanxiang Electric Co., Ltd.

Hunan Yuanxiang produces high-quality integrated stepper motors for a variety of industries, focusing on durability and energy efficiency in their designs.

17. Zhejiang Xianfeng Motor Co., Ltd.

Xianfeng Motor specializes in high-performance integrated stepper motors that are used in precision applications such as robotics, automation, and automotive sectors.

18. Changsha Xinlong Electric Co., Ltd.

Changsha Xinlong Electric is known for its focus on energy-efficient integrated stepper motors. Their products are widely used in industrial and medical applications.

19. Shanghai Zhenhua Electronics Co., Ltd.

Shanghai Zhenhua Electronics produces advanced Integrated stepper servo motors, with a focus on performance optimization and precision control.

20. Taizhou Aoyu Electronics Co., Ltd.

Taizhou Aoyu is a pioneer in integrated motor design, offering motors for various industrial applications that require high torque and precision.

Factors to Consider When Choosing a Stepper Motor Manufacturer

When selecting a stepper motor manufacturer, several key factors must be considered to ensure that you choose the right supplier for your needs. From product quality to customer service, each aspect plays a critical role in making an informed decision. In this article, we’ll explore the important elements you need to focus on when choosing the right stepper motor manufacturer.

1. Product Quality and Reliability

Product quality is one of the most crucial factors when selecting a stepper motor manufacturer. High-quality stepper motors should offer consistent performance, durability, and reliability. Before making a decision, ensure that the manufacturer adheres to quality standards and has a history of producing motors with low failure rates. Checking customer reviews, product specifications, and any certifications can help you gauge the manufacturer's reliability.

2. Product Range and Customization Options

Different applications require different types of stepper motors. A good manufacturer should offer a wide range of stepper motors, including unipolar, bipolar, and hybrid types. Furthermore, consider if the manufacturer provides customization options to meet your specific needs. Customization may include adjustments in size, voltage, torque, or specific performance features that can enhance the motor’s compatibility with your project.

3. Manufacturer Experience and Expertise

Experience is an essential factor when choosing a stepper motor manufacturer. A manufacturer with years of industry experience is likely to have in-depth knowledge of the challenges and innovations in stepper motor technology. Companies with expertise in stepper motors will be able to provide better recommendations and solutions that meet your unique requirements.

4. Price and Value for Money

While price shouldn’t be the only factor in your decision, it’s still an important consideration. Ensure that the price of the stepper motors aligns with the quality and features offered. Compare pricing across different manufacturers to gauge the value for money. Beware of manufacturers offering significantly lower prices, as this may indicate a compromise in quality.

5. Customer Support and After-Sales Service

Customer support is essential in any manufacturing relationship. A manufacturer that offers excellent customer service can provide you with guidance during installation, troubleshooting, and even after-sales support. Look for a manufacturer that provides timely responses to inquiries, has a well-organized support system, and offers warranties or guarantees for their products.

6. Delivery and Lead Time

The delivery time is another critical factor to consider. Depending on your project’s timeline, you may need stepper motors within a specific timeframe. Ensure that the manufacturer can meet your delivery deadlines and provide reliable shipping options. Additionally, ask about their lead time and whether they can accommodate urgent orders if necessary.

7. Manufacturing Location and Supply Chain

The location of the stepper motor manufacturer can impact both cost and delivery times. Domestic manufacturers may offer faster shipping and lower costs due to reduced import taxes and shipping fees. On the other hand, international manufacturers may offer lower base prices but come with longer shipping times. Assess the pros and cons of each option based on your specific needs and project timelines.

8. Testing and Certification

A reliable stepper motor manufacturer will have a rigorous testing process in place to ensure their motors meet high standards of performance and reliability. Check if the manufacturer conducts thorough quality control and testing procedures, such as load testing, vibration analysis, and thermal cycling. Certifications like ISO 9001 or CE marks are also indicators of the manufacturer’s commitment to quality.

9. Environmental Considerations

As sustainability becomes increasingly important, choosing a manufacturer that is committed to environmentally friendly practices can be a smart decision. Ensure the manufacturer follows eco-friendly practices, such as reducing energy consumption, recycling materials, and minimizing waste during the production process. This can not only benefit the environment but can also be a selling point for businesses that prioritize sustainability.

10. Reviews and Reputation

Finally, do some research into the manufacturer's reputation. Customer feedback and industry reviews can provide insight into the manufacturer’s credibility and product quality. A manufacturer with a solid reputation will likely have a long-standing record of producing reliable, high-performance stepper motors.

Choosing the right stepper motor manufacturer requires careful consideration of various factors, from product quality and pricing to customer service and delivery times. By focusing on these key aspects, you can make an informed decision that meets both your technical and business needs. Make sure to assess your options thoroughly before committing, as the right manufacturer will play a crucial role in the success of your project.

How Integrated Stepper Motors Are Revolutionizing Industries

Integrated stepper servo motors have become a cornerstone of many industries, offering significant advantages in terms of precision, energy efficiency, and ease of integration. These motors are revolutionizing fields like robotics, medical technology, and 3D printing, where high precision is critical.

Integrated stepper motors are transforming industries by offering an all-in-one solution that combines precision control, efficiency, and ease of integration. These motors are designed to simplify complex applications, reduce assembly time, and improve overall system performance. In this article, we’ll explore how integrated stepper motors are revolutionizing various sectors, from robotics to healthcare.

1. Enhancing Automation in Manufacturing

One of the most significant impacts of integrated stepper motors is on manufacturing automation. These motors are crucial for precision in assembly lines, robotic arms, and conveyor systems. By integrating the motor with the driver and controller into a single unit, manufacturers can reduce space requirements and simplify the design of automated systems.

Integrated stepper motors allow for better synchronization and more accurate movement control, which improves production efficiency and reduces errors. With less wiring and fewer components, the systems are also easier to maintain and troubleshoot, leading to increased uptime and lower operational costs.

2. Revolutionizing Robotics and Motion Control

Robotics is another field that benefits greatly from Integrated stepper servo motors. These motors provide precise positioning and smooth movement control, making them ideal for robotic applications. Whether it's for pick-and-place machines, surgical robots, or drones, integrated stepper motors enable robots to perform tasks with high accuracy and reliability.

The integration of the motor, controller, and driver into one unit reduces the overall size and complexity of robotic systems. This not only makes robots more efficient but also enhances their ability to function in smaller, more compact spaces. Additionally, integrated stepper motors enable advanced motion control algorithms, improving the flexibility and capabilities of robotic systems.

3. Advancements in Healthcare and Medical Equipment

In healthcare, integrated stepper motors are playing a vital role in the development of medical equipment that requires precise control and movement. Devices like infusion pumps, automated syringe pumps, and medical imaging equipment rely on stepper motors for accurate positioning and fluid control.

The integration of the motor with the controller and driver allows for more compact and reliable designs, which is crucial in medical devices where space and reliability are paramount. Integrated stepper motors also reduce the complexity of manufacturing, leading to faster production times and lower costs for medical equipment.

4. Boosting the Performance of 3D Printers

3D printing technology has witnessed tremendous growth in recent years, and integrated stepper motors are playing a crucial role in this revolution. These motors are used to drive the movement of the printhead and build platform, ensuring that each layer of material is precisely placed during the printing process.

Integrated stepper motors enable better motion control, reducing the chances of print errors and ensuring high-quality results. Additionally, they simplify the overall design of 3D printers by eliminating the need for separate motor drivers and controllers. This leads to lower costs for manufacturers and easier integration for users.

5. Improving Consumer Electronics and Smart Devices

Integrated stepper servo motors are also enhancing the performance of consumer electronics and smart devices. In products such as printers, cameras, and smart home devices, stepper motors are used to control movement with high precision. The integration of the motor, driver, and controller in a single unit allows for a more compact design and more efficient energy consumption.

This integration not only reduces the size of the components but also improves the overall reliability and lifespan of the devices. For example, in smart cameras, integrated stepper motors enable precise focusing mechanisms, while in home automation systems, they allow for accurate positioning of various components like shutters, blinds, and screens.

6. Advancing Aerospace and Defense Applications

In the aerospace and defense sectors, integrated stepper motors are used in various applications, including control surfaces, actuators, and positioning systems. The precision and reliability offered by these motors are critical in environments where accuracy is a matter of safety and performance.

Integrated stepper motors simplify the design and reduce the weight of aerospace systems. This is particularly important in applications such as satellite communication, flight control, and missile guidance systems, where every ounce counts, and failure is not an option.

7. Enabling the Future of Electric Vehicles (EVs)

As the world shifts toward sustainable transportation, Integrated stepper servo motors are becoming increasingly important in the electric vehicle (EV) industry. These motors are used in systems such as electric power steering, automated doors, and other positioning systems within EVs. Their precision, reliability, and efficiency make them ideal for use in these cutting-edge vehicles.

By integrating the motor, driver, and controller, manufacturers can reduce the overall weight and complexity of EV systems, contributing to more efficient and reliable performance. Furthermore, the reduced number of components and wiring helps to streamline production and reduce costs.

8. Supporting the Growth of IoT and Smart Technologies

Integrated stepper servo motors are also driving the growth of Internet of Things (IoT) devices and other smart technologies. These motors can be found in a variety of IoT applications, from smart locks to automated cameras and robotic vacuum cleaners. The compact design and ease of integration make them perfect for these types of devices.

The efficiency of integrated stepper motors allows for longer battery life, which is essential for portable IoT devices. Additionally, their precision and reliability ensure that smart devices can perform tasks accurately and autonomously, making them more useful and convenient for users.

Integrated stepper motors are indeed revolutionizing industries across the board by offering higher precision, reliability, and energy efficiency. From manufacturing automation to healthcare devices, robotics, and consumer electronics, these motors are enabling technological advancements and enhancing system performance. As industries continue to evolve, the integration of stepper motors will play a crucial role in shaping the future of automation, innovation, and smart technologies.

Conclusion

China remains at the forefront of the integrated stepper motor market, with its top manufacturers pushing the boundaries of motor technology. By offering cutting-edge products, cost-effective solutions, and high-performance motors, these manufacturers continue to lead the way in industries ranging from industrial automation to consumer electronics.

FAQs

1. What is the difference between integrated stepper motors and regular stepper motors?

Integrated stepper motors combine both the motor and controller into one unit, whereas regular stepper motors require an external controller.

2. Why is China considered a leader in stepper motor manufacturing?

China’s strong manufacturing infrastructure, competitive pricing, and technological advancements make it a leader in the stepper motor industry.

3. How do integrated stepper motors improve performance in industrial applications?

Integrated stepper motors reduce complexity and improve efficiency by combining the motor and controller, leading to better performance and ease of use.

4. What are the common industries using integrated stepper motors?

Industries like robotics, automation, 3D printing, and medical technology commonly use integrated stepper motors for their high precision and efficiency.

5. How can I choose the right integrated stepper motor manufacturer?

Consider factors such as quality, reputation, customer support, and R&D capabilities when selecting a manufacturer.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Oʻzbekcha

latviešu

Azərbaycan dili

Български

Català