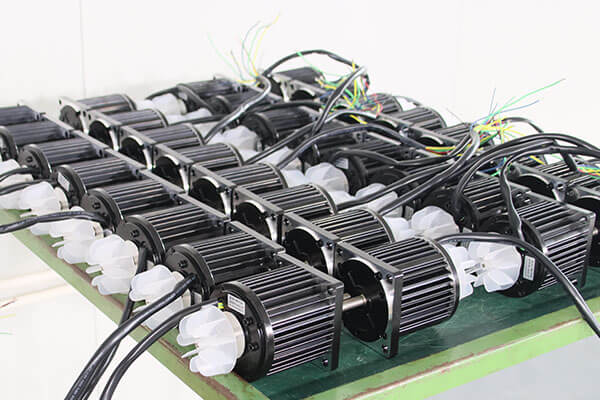

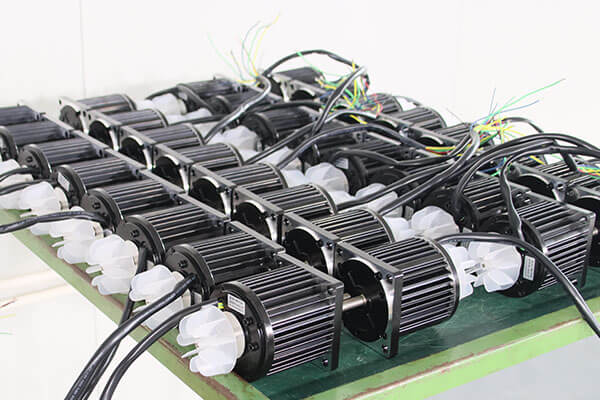

Integrated servo motors are revolutionizing the way industries approach motion control and automation. Combining the functionalities of a traditional servo motor with built-in electronics, these motors simplify system design, reduce wiring, and improve overall performance. In this article, we delve into the specifics of integrated servo motors, their applications, advantages, and how they are transforming industries worldwide.

Understanding the Basics of Integrated Servo Motors

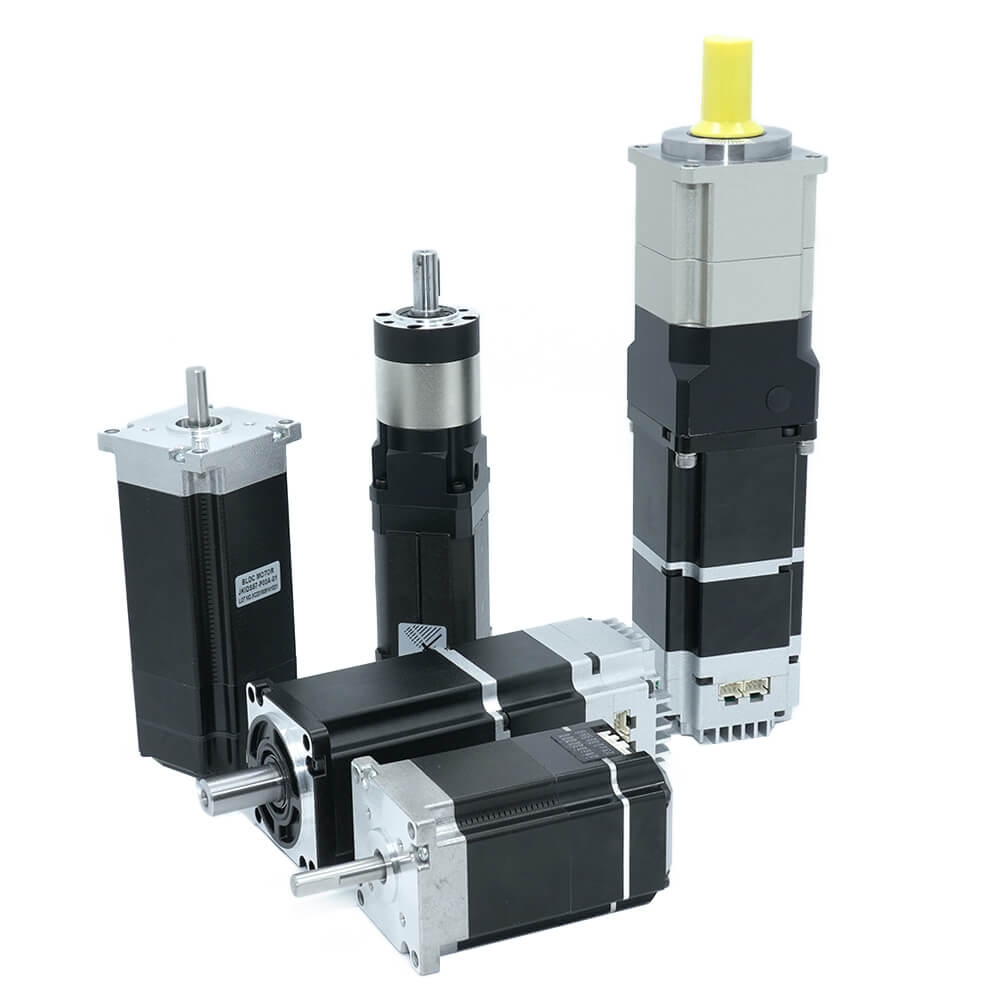

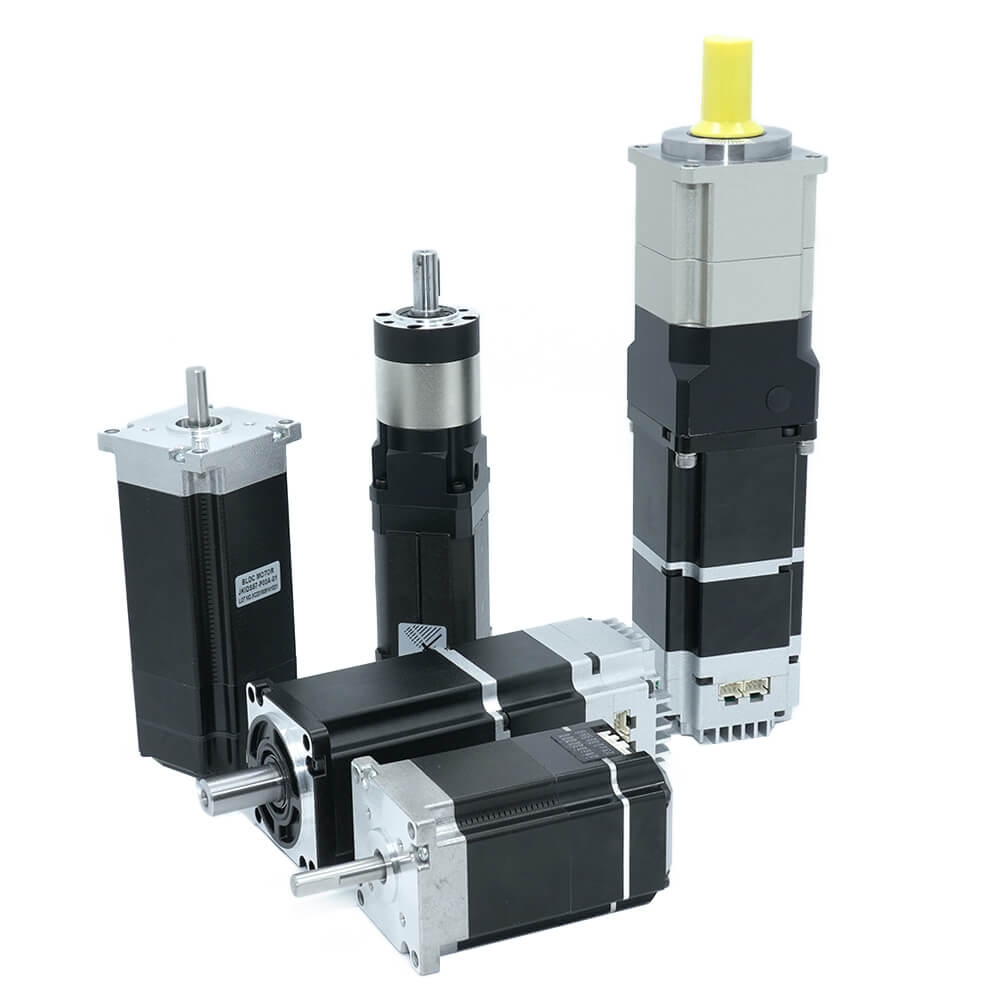

An integrated servo motor is an advanced motion control device that combines the key components of a traditional servo system—such as the motor, controller, driver, and feedback mechanism—into a single, compact unit. This integration eliminates the need for separate external controllers and extensive wiring, simplifying system design and installation.

The primary purpose of an integrated servo motor is to deliver precise control over motion parameters like position, speed, and torque while minimizing the complexity of the setup. These motors are widely used in industrial automation, robotics, medical devices, and various other fields requiring accurate and reliable motion control.

Key Components of an Integrated Servo Motor

Servo Motor:

The core of the system, responsible for generating the mechanical motion. Servo motors are known for their ability to provide smooth, controlled, and accurate rotational or linear movement.

Integrated Controller:

The built-in controller processes commands and determines how the motor should operate. It manages motion profiles, coordinates tasks, and ensures the motor follows precise instructions.

Integrated Driver (Amplifier):

The driver translates control signals from the controller into electrical power, providing the necessary current and voltage to operate the motor efficiently.

Feedback System:

This includes encoders or resolvers that monitor the motor’s performance in real time. The feedback system ensures that the motor achieves the desired position, speed, and torque with high accuracy.

How Integrated Servo Motors Work

Integrated servo motor operate using a closed-loop control system. Here’s a simplified explanation of their working process:

Command Input:

The motor receives input commands for desired motion, such as a specific position or speed.

Signal Processing:

The integrated controller processes the input and calculates the required motion parameters.

Motor Activation:

The integrated driver powers the motor according to the processed instructions.

Feedback Monitoring:

The encoder or resolver continuously measures the motor’s actual performance and sends feedback to the controller.

Error Correction:

If there's any deviation from the desired output, the controller adjusts the motor's operation in real-time to maintain accuracy.

This seamless integration of control, driving, and feedback enables precise and efficient motion control, making integrated servo motors ideal for demanding applications.

Advantages of Integrated Servo Motors

1. Simplified System Design

By consolidating multiple components into one, integrated servo motors reduce the complexity of motion control systems. This streamlined approach:

Minimizes the need for external wiring.

Reduces the footprint of the system.

Simplifies installation and maintenance processes.

2. Enhanced Reliability

integrated servo motors are designed to operate as a single unit, which minimizes potential points of failure. The compact design ensures consistent performance in challenging environments, reducing downtime and maintenance costs.

3. Cost Efficiency

While the initial investment might seem higher than traditional systems, integrated servo motors offer significant cost savings over time by reducing:

4. Improved Performance

integrated servo motors excel in delivering precise control, thanks to their advanced feedback systems and built-in controllers. They provide:

High positional accuracy: Ideal for applications demanding precise movements.

Fast response times: Ensuring seamless operation in dynamic environments.

Energy efficiency: Optimized power usage reduces overall operational costs.

5. Space Optimization

Their compact design makes integrated servo motors perfect for applications where space is at a premium. This feature is especially beneficial in robotics, medical equipment, and compact industrial machinery.

Applications of Integrated Servo Motors

integrated servo motors are used across a wide range of industries due to their versatility and reliability. Here are some of their primary applications:

1. Robotics

In robotics, precise motion control is crucial. Integrated servo motors are extensively used in robotic arms, automated guided vehicles (AGVs), and collaborative robots (cobots) to achieve smooth and accurate movements.

2. Medical Equipment

Medical devices such as surgical robots, diagnostic machines, and prosthetics rely on integrated servo motors for their high precision, compact size, and quiet operation.

3. Packaging and Material Handling

Integrated servo motors enhance the speed and accuracy of packaging machinery, conveyor systems, and pick-and-place equipment, ensuring efficiency in industrial processes.

4. CNC Machines

In computer numerical control (CNC) machines, integrated servo motors ensure precise cutting, drilling, and shaping operations, leading to high-quality finished products.

5. Automotive Industry

From assembly lines to electric vehicle (EV) systems, integrated servo motors play a pivotal role in enhancing automation and efficiency in the automotive sector.

6. Aerospace

The aerospace industry utilizes integrated servo motors for applications like actuation systems, flight control surfaces, and satellite positioning, where reliability and precision are paramount.

Key Features to Look for in an Integrated Servo Motor

When selecting an integrated servo motor, it’s essential to consider the following features to ensure optimal performance:

1. Power and Torque Ratings

Choose a motor with adequate power and torque capabilities to meet the demands of your application.

2. Feedback Accuracy

High-resolution encoders or resolvers provide better feedback and improve the precision of the motor.

3. Communication Protocols

Modern integrated servo motors support various communication protocols, such as:

EtherCAT

CANopen

Modbus

Ethernet/IP

These protocols enable seamless integration with existing automation systems.

4. Environmental Resistance

For harsh environments, ensure the motor has a robust design with features like:

IP-rated enclosures.

Resistance to temperature fluctuations.

Protection against dust, water, and vibrations.

5. Programmability

Integrated servo motors with advanced programmability allow for easier customization and adaptation to specific tasks.

Integrated Servo Motors vs. Traditional Servo Motors

To fully appreciate the benefits of integrated servo motors, it’s essential to compare them with traditional servo motors:

| Feature | Integrated Servo Motor | Traditional Servo Motor |

| Design | All-in-one unit | Requires separate controller and driver |

| Wiring Complexity | Minimal | Extensive |

| Installation | Simple and quick | Time-consuming |

| Space Requirements | Compact | Larger footprint |

| Maintenance | Easier due to fewer components | More complex due to multiple components |

| Cost | Higher upfront cost, but lower overall cost | Lower upfront cost, higher long-term cost |

The Future of Integrated Servo Motors

The demand for integrated servo motors is growing rapidly as industries continue to prioritize automation and efficiency. Innovations in motor design, such as improved thermal management and AI-based control algorithms, are set to enhance their capabilities further. As manufacturing processes become more sophisticated, integrated servo motors will remain at the forefront of motion control technology.

Conclusion

Integrated servo motors represent a significant leap forward in motion control technology. Their ability to combine multiple components into a single, compact unit offers unparalleled advantages in terms of efficiency, reliability, and performance. From robotics to aerospace, these motors are driving innovation across industries and enabling businesses to achieve their automation goals.

By combining multiple components into a single package, integrated servo motors simplify system design, reduce wiring complexity, and enhance overall reliability—offering significant advantages over traditional servo systems.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Oʻzbekcha

latviešu

Azərbaycan dili

Български

Català