Introduction

Stepper motors are indispensable in numerous high-tech industries, including robotics, automation, and even 3D printing. These motors are known for their precision and reliability, making them an essential component in any technology requiring controlled, incremental movement. China, as a manufacturing powerhouse, has become one of the global leaders in stepper motor production, with countless companies offering high-quality, innovative solutions. If you're looking for a reliable stepper motor supplier, China is where you'll find some of the best.

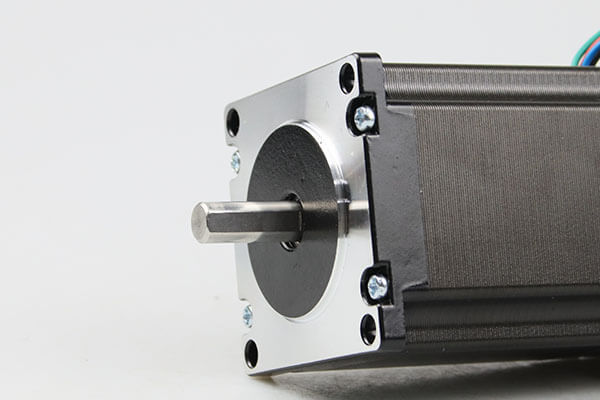

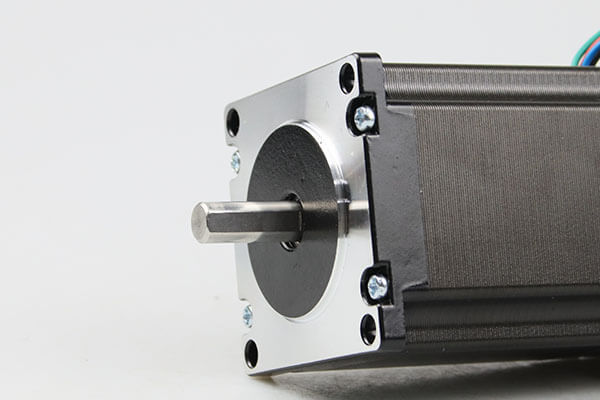

What is a Stepper Motor?

Before diving into the stepper motor manufacturers, let's first understand what a stepper motor is. Simply put, a stepper motor is an electric motor that divides a full rotation into equal steps. This makes them perfect for applications requiring precise control over the rotational position, such as robotics, CNC machines, and medical equipment.

The key advantage of stepper motors over traditional DC motors is their ability to move in discrete steps, providing greater accuracy in movement. These motors find use in applications like automated camera systems, industrial robots, and even in smaller-scale applications like vending machines.

Stepper Motor Basic:

A stepper motor is an electric motor that rotates its shaft in precise, fixed-degree steps. Due to its internal structure, you can track the shaft's exact angular position by counting the steps—no sensor needed. This precision makes stepper motors ideal for many applications.

Stepper Motor System:

The operation of a stepper motor system revolves around the interaction between the rotor and stator. Here’s a detailed look at how a typical stepper motor works:

Signal Generation: A controller generates a sequence of electrical pulses that represent the desired movement.

Driver Activation: The driver receives the signals from the controller and energizes the motor windings in a specific sequence, creating a rotating magnetic field.

Rotor Movement: The magnetic field generated by the stator interacts with the rotor, causing it to rotate in discrete steps. The number of steps corresponds to the pulse frequency sent by the controller.

Feedback (Optional): In some systems, a feedback mechanism, such as an encoder, may be used to ensure that the motor has moved the correct distance. However, many stepper motor systems operate without feedback, relying on the precise control of the driver and controller.

Hybrid Stepper Motors Features:

A hybrid stepper motor merges the best characteristics of permanent magnet and variable reluctance technologies to provide superior performance. It is often referred to as a hybrid motor due to its combination of features from both motor types.

The rotor in a hybrid stepper motor contains a permanent magnet, while the stator has multiple coils that interact with the rotor to create a magnetic field. The rotor is designed with teeth or poles that align with the stator poles, allowing for finer control over the step resolution. This combination of permanent magnet and variable reluctance design provides high torque, excellent step resolution, and minimal backlash, making hybrid stepper motors highly efficient.

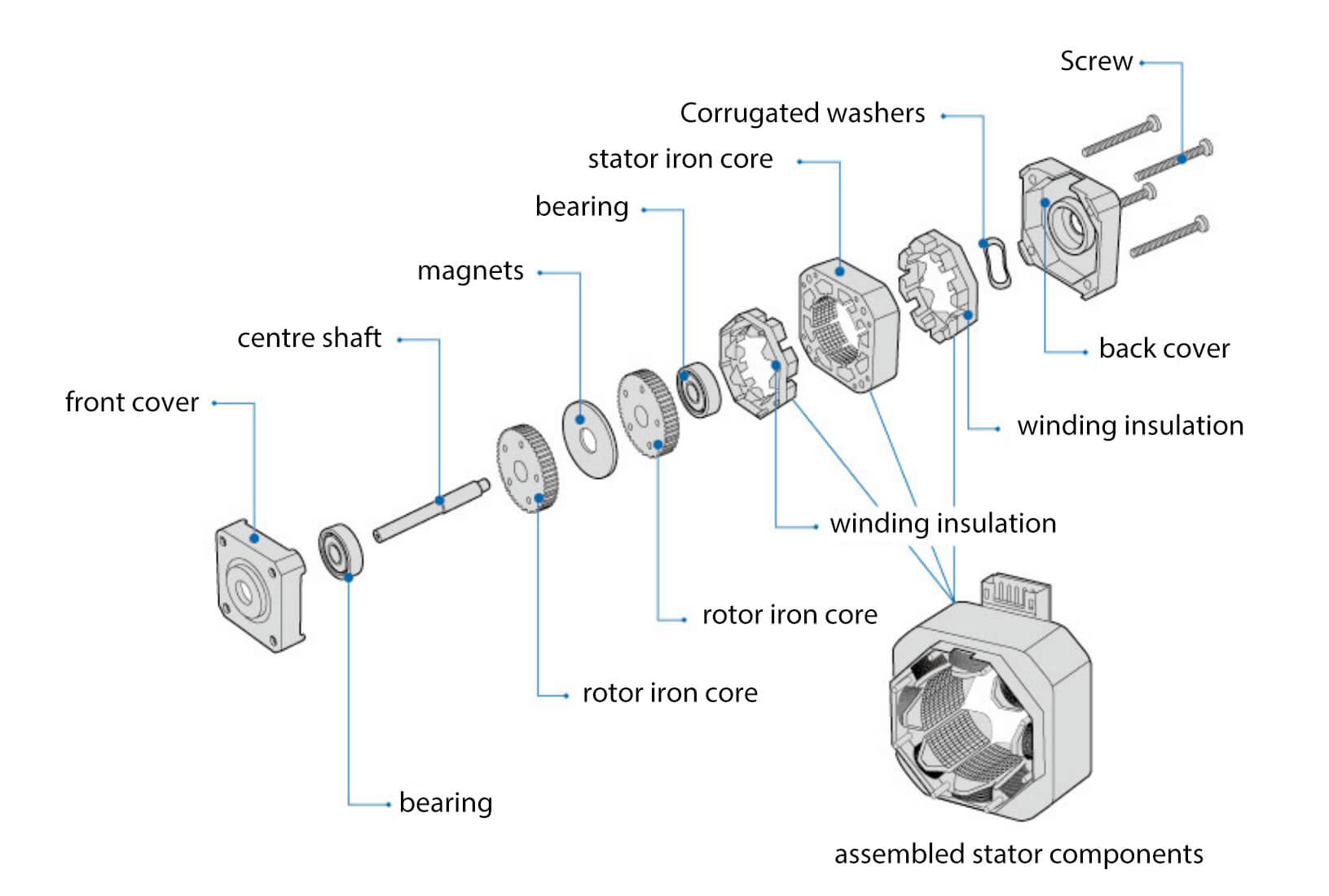

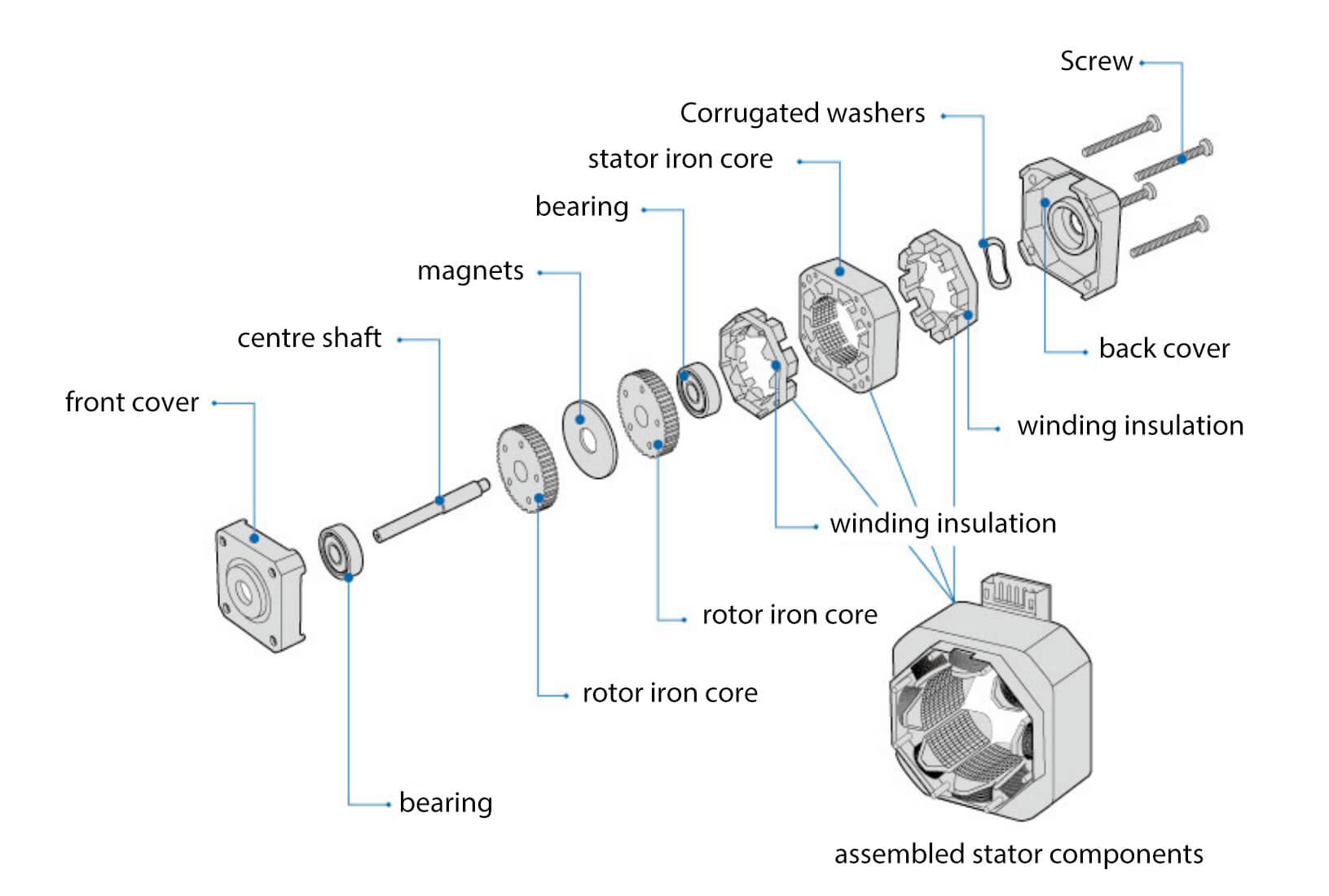

Hybrid Stepper Motors Structure:

Factors to Consider When Choosing a Stepper Motor Manufacturer

When choosing a stepper motor supplier, there are several factors to consider:

Now, let’s explore the top 20 stepper motor manufacturers in China that stand out in the industry.

The structure of a hybrid stepper motor consists of several key components:

Stator, rotor, cover, shaft, bearing, magnets, iron cores, wires, winding insulation, corrugated washers and so on...

Working Principle of Hybrid Stepper Motor Structure:

How Does a Stepper Motor Work?

Stepper motors operate based on the interaction between magnetic fields and current-carrying coils. Here is a step-by-step breakdown of how they function:

1. Magnetic Fields and Coils

The basic components of a stepper motor include a rotor (the rotating part) and a stator (the stationary part). The rotor typically has permanent magnets, and the stator contains multiple coils of wire. When electricity flows through these coils, it creates magnetic fields that interact with the rotor’s permanent magnets.

2. Stepping Process

Stepper motors are designed to move in small, distinct steps. These steps are created by energizing different coils in sequence, causing the rotor to align with the magnetic field generated by the stator. Each time a coil is energized, the rotor rotates a small increment, or "step," in the direction of the field.

3. Types of Stepping

The rotation of a stepper motor is achieved in different stepping modes, such as:

Different Types of Stepper Motors

There are three primary types of stepper motors, each with its own advantages and use cases. Understanding these types will help you choose the right motor for your application.

1. Permanent Magnet Stepper Motors

Permanent magnet stepper motors use a permanent magnet as the rotor. These motors are simple in construction, inexpensive, and provide high torque at low speeds. They are best suited for applications that require low to medium precision, such as in printers and small robots.

2. Variable Reluctance Stepper Motors

Variable reluctance stepper motors do not use permanent magnets. Instead, they rely on the rotor’s ability to change its magnetic reluctance as it moves. These motors are known for their high-speed capabilities but generally offer lower torque compared to permanent magnet stepper motors. They are used in applications where speed is more critical than torque, such as in certain types of pumps or medical equipment.

3. Hybrid Stepper Motors

Hybrid stepper motors combine the best features of both permanent magnet and variable reluctance motors. They provide high torque, smooth motion, and precise control, making them the most commonly used type in advanced applications like 3D printers, CNC machines, and robotics. Hybrid motors offer a balanced combination of performance, efficiency, and cost-effectiveness.

Top 20 Stepper Motor Manufacturers in China

1. Leadshine Technology

Leadshine Technology is one of the most reputable names in the stepper motor manufacturer. They specialize in manufacturing high-performance motion control products, including stepper motors, servo motors, and controllers. Their products are known for their reliability, energy efficiency, and precision. Leadshine has a global presence, serving industries ranging from industrial automation to medical equipment.

2. Moons'

With over 25 years of experience, Moons' is a trusted brand in the stepper motor market. Their stepper motors are designed for applications requiring precise positioning and speed control. They offer a wide range of products, including closed-loop stepper systems, which reduce energy consumption and increase performance.

3. Shenzhen Smoore Technology

Smoore is a leader in both the electric motor and e-cigarette industries. Their stepper motors are used in a variety of applications, including robotics and industrial machinery. Known for their innovative approach, Smoore continually pushes the envelope in motor technology.

4. MinebeaMitsumi

This global company manufactures high-quality stepper motors, widely used in various applications from printers to industrial automation. Their products are known for low noise and high accuracy. MinebeaMitsumi's research-driven approach ensures they remain ahead of the curve in innovation.

5. Sanyo Denki

Sanyo Denki, a subsidiary of the SanYo Group, is a leading stepper motor manufacturer of electric motors, including stepper motors. Their motors are widely used in precision machinery, robotics, and HVAC systems, offering unmatched reliability and long service life.

6. Changzhou Jkongmotor Co., Ltd

Jkongmotor specializes in precision motors, including stepper motors for drones and robotics. They focus on high-performance and lightweight solutions, offering products that cater to both industrial and hobbyist needs. Jkongmotor is a professional stepper motor manufacturer and well-regarded for its commitment to quality and innovation.

7. Wuxi Yidexin Electronics

Wuxi Yidexin is known for manufacturing stepper motors that cater to the automotive, medical, and home appliance industries. Their products are characterized by durability and high performance, even in challenging environments.

8. Shenzhen Cancon Technology

Shenzhen Cancon has made a name for itself in the field of stepper motors with its strong focus on quality and innovation. Their motors are commonly used in the automation, medical, and consumer electronics sectors.

9. Jinan Stepper Motor Co., Ltd.

Specializing in custom stepper motors, Jinan Stepper Motor Co. provides tailored solutions to meet specific client needs. Their motors are ideal for use in machines that require precise motion control, such as CNC machines and medical devices.

10. Taizhou Shuanglong Electric Co.

Taizhou Shuanglong Electric has established itself as a competitive player in the stepper motor market. Their range of products includes stepper motors with superior torque and reliability, designed for use in industrial automation, packaging, and medical equipment.

11. Baosheng Motor

Baosheng Motor is known for offering reliable and affordable stepper motors. They specialize in both standard and customized solutions, which are widely used in automotive, robotics, and industrial sectors.

12. Hangzhou HSD Motor Co., Ltd.

HSD Motor has earned a strong reputation for its high-performance stepper motors. The company focuses on offering precision-driven products for industries like robotics, medical devices, and industrial automation.

13. Lynxmotion

Lynxmotion specializes in stepper motors for robotic applications. Their products are designed for superior performance in motion control, making them a top choice for those working in the robotics and automation industries.

14. Shenzhen Daheng Power

Daheng Power offers a range of high-quality stepper motors known for their low power consumption and long life cycle. They are primarily used in industrial machinery, robotics, and medical systems.

15. Shenzhen Hivolt Technologies

Hivolt Technologies focuses on the production of stepper motors that are optimized for industrial applications. They are known for their durability, precision, and energy efficiency, making them a popular choice in manufacturing and automation sectors.

16. Siyu Motors

Siyu Motors provides affordable yet reliable stepper motors. Their products are often used in home appliances, medical devices, and consumer electronics.

17. Fujikura Ltd.

Fujikura has a long legacy of manufacturing high-quality electric motors, including stepper motors. Their products are commonly used in robotics, industrial machinery, and automation.

18. Weho Motor

Weho Motor focuses on energy-efficient motors and is known for producing stepper motors with low energy consumption. Their products are widely used in various industrial sectors.

19. Changzhou BesFoc Motor Co., Ltd

BesFoc Motor specializes in integrated stepper motors for automation, industrial control, and medical systems. They are known for their high precision and reliable performance.

20. Zhenhua Motor Co., Ltd.

Zhenhua Motor Co. has earned a reputation for producing robust and reliable stepper motors. Their motors are used in a variety of applications, from automotive to robotics, thanks to their performance and durability.

Why Choose Chinese Stepper Motor Manufacturers?

China's dominance in the stepper motor manufacturer is due to a combination of competitive pricing, large-scale production capabilities, and continuous investment in technological advancements. With an ever-growing focus on automation and precision, Chinese manufacturers offer high-quality stepper motors that meet global standards at a fraction of the cost compared to their Western counterparts.

Advantages of Stepper Motors

Stepper motors are highly regarded for their ability to provide precise control and reliable performance. Below are some of the key advantages of using stepper motors:

1. High Precision and Accuracy

The primary advantage of a stepper motor is its ability to provide precise movement. Each step represents a specific angle of rotation, allowing the motor to achieve accurate positioning without the need for encoders or other feedback mechanisms.

2. Open-Loop Control

Unlike other types of motors, stepper motors can be controlled in an open-loop configuration. This means they do not require feedback to determine their position or velocity, making them simpler and more cost-effective for many applications.

3. High Torque at Low Speeds

Stepper motors provide high torque even at low speeds. This characteristic makes them perfect for applications where consistent torque is required, such as in robotics, conveyor systems, and printers.

4. Reliability and Durability

Due to their simple design and lack of brushes (in most stepper motor types), stepper motors are known for their durability and long lifespan. They are often used in environments where consistent performance is required for extended periods.

Disadvantages of Stepper Motors

Despite their many advantages, stepper motors also have some drawbacks that need to be considered when choosing the right motor for an application.

1. Lower Efficiency

Stepper motors tend to have lower efficiency compared to other types of motors like DC motors. This is because they often draw more current, especially when idling or under light load conditions.

2. Limited Speed and Acceleration

While stepper motors provide precise control, their maximum speed and acceleration capabilities are generally lower than other types of motors, such as servo motors. This limits their use in high-speed or high-acceleration applications.

3. Vibration and Noise

Stepper motors can generate vibration and noise, especially at low speeds or during rapid acceleration. This can be a concern in applications where smooth, quiet operation is important.

Applications of Stepper Motors

Stepper motors have a wide range of applications across various industries. Some of the most common use cases include:

1. 3D Printers

Stepper motors are the backbone of 3D printing technology. They precisely control the movement of the print head and the build platform, ensuring accurate and repeatable printing processes.

2. CNC Machines

In CNC (computer numerical control) machines, stepper motors are used to move tools along the X, Y, and Z axes. The precise control offered by stepper motors allows for high-precision machining of parts.

3. Robotics

Robots rely heavily on stepper motors to achieve controlled movements and maintain accurate positioning. Stepper motors are used in robot arms, wheels, and other components that require precise motion.

4. Camera Systems

In camera systems, stepper motors are used for controlling the zoom and focus mechanisms, providing accurate and smooth adjustments without the need for complex feedback systems.

5. Automotive Systems

Stepper motors are also used in automotive systems, such as for controlling the positioning of seats, mirrors, and other adjustable components.

Choosing the Right Stepper Motor for Your Application

When selecting a stepper motor for a specific application, several factors should be taken into account:

Torque Requirements: Ensure the motor provides sufficient torque for the load it will be driving.

Speed and Resolution: Choose a motor with the appropriate speed and resolution for your needs.

Size and Form Factor: Consider the available space and ensure the motor fits within your design constraints.

Power Supply: Ensure the motor is compatible with the power supply and driver circuit.

By considering these factors and understanding the basic workings of stepper motors, you can make an informed decision when integrating them into your systems.

Conclusion

China remains at the forefront of stepper motor production, offering a diverse range of stepper motor manufacturer who can cater to various industrial needs. Whether you're looking for a custom solution or off-the-shelf motors, these top 20 stepper motor manufacturer represent the best in the business. When sourcing stepper motors from China, ensure you consider factors such as quality, service, and cost to make an informed decision for your business.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Oʻzbekcha

latviešu

Azərbaycan dili

Български

Català