What is Bldc Motor?

A BLDC motor (Brushless DC motor) is a type of electric motor that operates using direct current (DC) electricity without the use of brushes. Unlike traditional brushed motors, BLDC motors rely on electronic commutation to control the rotation of the motor. This is achieved through sensors and an electronic controller, which regulate the flow of current to the motor windings based on the rotor's position.

In the rapidly evolving world of electric motors, Brushless DC (BLDC) motors have emerged as a key component for applications requiring high efficiency, long lifespan, and minimal maintenance. China, a global manufacturing powerhouse, has become a leader in the production of brushless DC motors, offering businesses and industries top-tier solutions that cater to a wide range of needs. This article delves into the factors that make Chinese BLDC motor manufacturers stand out, their advantages, applications, and how they contribute to the advancement of modern electric motor technology.

Key Features of BLDC Motors:

High Efficiency: BLDC motors are known for their energy efficiency, making them ideal for applications where power savings are critical.

Durability: The absence of brushes reduces mechanical wear and tear, leading to longer operational lifespans.

Low Maintenance: With no brushes to replace, BLDC motors require less maintenance compared to traditional motors.

Smooth Operation: They provide smooth torque and precise speed control, suitable for sensitive applications.

Compact and Lightweight: BLDC motors are typically smaller and lighter than brushed motors of equivalent power.

How a BLDC Motor Works:

A BLDC motor operates using electronic commutation instead of mechanical brushes. This design uses a combination of a rotor with permanent magnets and a stator with windings, along with a controller that manages the current flow through the windings. Here is a detailed explanation of its working principle:

1. Structure of a BLDC Motor:

Rotor: Contains permanent magnets that rotate inside the motor.

Stator: Composed of multiple coils or windings that produce a rotating magnetic field.

Electronic Controller: Includes sensors (like Hall-effect sensors) or back EMF detection systems to determine the rotor's position and regulate the current flow.

2. Principle of Operation:

The BLDC motor works by generating a magnetic field in the stator, which interacts with the magnetic field of the rotor to create motion.

Step-by-Step Process:

Electronic Commutation:

The controller energizes specific stator windings in a sequence, creating a rotating magnetic field.

The position of the rotor is detected by sensors or by analyzing back EMF, allowing the controller to time the switching of current precisely.

Interaction of Magnetic Fields:

The rotor's permanent magnets align with the rotating magnetic field generated by the stator.

This alignment creates torque, causing the rotor to spin.

Continuous Rotation:

As the rotor moves, the controller switches the current to the next set of windings in the correct sequence.

This process repeats continuously, maintaining a smooth and efficient rotation.

3. Control Methods:

BLDC motors can operate in two primary modes:

Sensor-Based Control: Uses position sensors (e.g., Hall-effect sensors) to detect rotor position and manage commutation accurately.

Sensorless Control: Relies on feedback from back EMF (Electromotive Force) generated by the spinning rotor for commutation.

4. Benefits of Electronic Commutation:

Eliminates the need for physical brushes, reducing wear and maintenance.

Enables precise control over speed and torque.

Allows for quieter operation and higher efficiency.

Applications of BLDC Motors:

Automotive: Electric vehicles (EVs), power steering systems, and HVAC fans.

Industrial: Robotics, conveyor belts, and CNC machines.

Consumer Electronics: Drones, computer fans, and electric scooters.

Medical Equipment: Ventilators, pumps, and prosthetic devices.

Household Appliances: Washing machines, refrigerators, and air conditioners.

Advantages of BLDC Motors:

Higher efficiency and performance.

Quiet operation with minimal noise.

Longer service life due to reduced wear.

Improved thermal performance as the heat is generated in the stator, which is easier to cool.

Challenges:

Higher initial cost compared to brushed motors.

Complex electronic control systems.

Dependence on rare earth materials for permanent magnets, which can affect cost and availability.

China has become a global hub for Brushless DC (BLDC) motor production, renowned for its innovation, high-quality products, and competitive pricing. In this article, we explore the top 15 BLDC motor manufacturers in China, detailing their unique capabilities and offerings. Whether you’re looking for high-performance motors or cost-effective solutions, these companies stand out in the market.

1. Maxon Motor (Suzhou) Co., Ltd.

Maxon Motor is a leader BLDC motor manufacturers, offering advanced solutions for robotics, medical devices, and aerospace applications. With Swiss origins, its Suzhou factory combines precision engineering with local expertise, ensuring top-notch quality.

Key Features:

High torque-to-weight ratio.

Customizable motor designs.

Application-specific solutions.

2. Shenzhen Topband Co., Ltd.

Shenzhen Topband specializes in intelligent motor systems, focusing on BLDC motors for smart home devices, electric vehicles, and industrial automation. Their motors are known for energy efficiency and durability.

Key Features:

3. Changzhou Fulling Motor Co., Ltd.

Fulling Motor is renowned for its versatile product line, catering to industries like healthcare, automation, and consumer electronics. Their BLDC motors are reliable and efficient, with a focus on innovation.

Key Features:

4. Ningbo Zhongda Leader Intelligent Transmission Co., Ltd.

Zhongda Leader specializes in intelligent motion control solutions. Their BLDC motors are widely used in industrial robots, conveyor systems, and medical equipment.

Key Features:

Advanced production facilities.

Integration of motors with controllers.

Strong after-sales support.

5. Jing-Jin Electric (JJE)

Jing-Jin Electric is a pioneer in the electric vehicle industry, focusing on high-performance BLDC motors for automotive applications. Their technology emphasizes efficiency and sustainability.

Key Features:

High-performance motors for EVs.

Cutting-edge thermal management systems.

Collaboration with global automakers.

6. Welling Motor

Welling Motor is a subsidiary of Midea Group, a leading global appliance BLDC motor manufacturers. They produce BLDC motors for a variety of applications, including HVAC systems, washing machines, and refrigerators.

Key Features:

High production capacity.

Integration with home appliances.

Energy-efficient motor solutions.

7. Wolong Electric Group

Wolong Electric Group offers an extensive range of BLDC motors, serving industries like automation, HVAC, and renewable energy. Their commitment to research and innovation has earned them a solid reputation.

Key Features:

8. Zhejiang Jinlong Electrical Machinery Co., Ltd.

Jinlong is a prominent BLDC motor manufacturers, widely used in handheld devices, drones, and small appliances. They are known for precision and cost-effective production.

Key Features:

9. Shanghai Moons’ Electric Co., Ltd.

MOONS’ Electric specializes in motion control and BLDC motors for industrial automation and lighting systems. Their products are synonymous with reliability and performance.

Key Features:

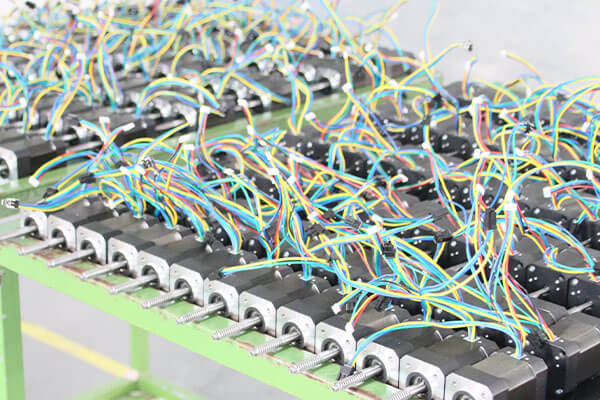

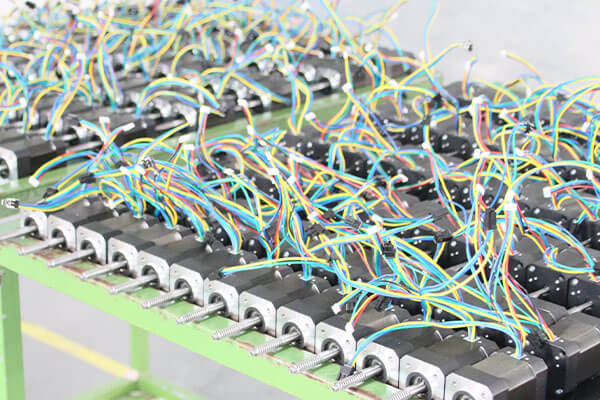

10. Changzhou BesFoc Motor Co., Ltd.

BesFoc Motor is a professional stepper motor and BLDC motor manufacturer, focuses on micro-motor technology, with a product line that includes BLDC motors for medical devices, automotive systems, and consumer electronics.

Key Features:

Extensive product customization.

High production capacity.

Strong emphasis on innovation.

11. MinebeaMitsumi (China)

MinebeaMitsumi is a global leader in precision engineering, producing high-quality BLDC motors in its Chinese facilities. Their motors cater to industries like aerospace, healthcare, and IT.

Key Features:

12. Zhejiang Founder Motor Co., Ltd.

Founder Motor is a major player in the automotive and industrial sectors, producing robust BLDC motors with a focus on reliability and longevity.

Key Features:

13. Shenzhen Kinmore Motor Co., Ltd.

Kinmore Motor specializes in small and mid-sized BLDC motors for automotive systems, home appliances, and personal care devices. Their commitment to quality ensures customer satisfaction.

Key Features:

14. Anhui Wannan Electric Machine Co., Ltd.

Wannan Electric Machine is a veteran BLDC motor manufacturer with a diverse range of BLDC motors for industrial applications. Their products are known for their robustness and efficiency.

Key Features:

Long-standing industry experience.

Focus on industrial applications.

High reliability and performance.

15. Nidec (Dongguan) Limited

Nidec is a global powerhouse in BLDC motor manufacturering, with its Dongguan facility playing a key role in producing high-quality BLDC motors for various applications, including consumer electronics and automotive systems.

Key Features:

Conclusion:

In summary, the BLDC motor operates by synchronizing the rotor's motion with an electronically controlled magnetic field. This advanced mechanism ensures durability, high efficiency, and superior performance across a wide range of applications.

These top 15 BLDC motor manufacturers in China represent the best in innovation, quality, and reliability. Each company offers unique strengths, making them valuable partners in diverse industries.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Oʻzbekcha

latviešu

Azərbaycan dili

Български

Català